Transition towards a more safe, sustainable and professional horticulture sector in Viet Nam

During the last decade greenhouse vegetable production has seen an enormous development in Vietnam. Farmers have invested in more modern greenhouse infrastructure and embraced improved growing technologies, greatly increasing productivity, product quality and profitability per production area. Although Vietnamese vegetable farmers have adopted more advance greenhouse production methods, the control of diseases and pests is still done through frequent and intensive application of chemical crop protection products.

The continuous shift towards more advanced greenhouse production methods and increasingly stricter market requirements in terms of food safety has created a momentum amongst Vietnamese farmers to start focussing on more sustainable product methods in which much less chemical crop protection products are applied. In practice this means that farmers are now more open to test and try technologies which can prevent pests and diseases to develop or to control pest and diseases in a biological way. Growing crops in this way means that farmers apply Integrated Pest Management (IPM).

Integrated Pest Management (IPM)

The goal of Integrated Pest Management (IPM) is to minimize this harm and control acceptable infestation levels rather than eradicate all undesired populations. This is why it is important to understand which control measures are justified in each case and use aggressive control measures only when other integrated management techniques don’t work. On a larger scope, integrated pest management advantages include the promotion of environmental protection and sustainable agriculture in the long run.

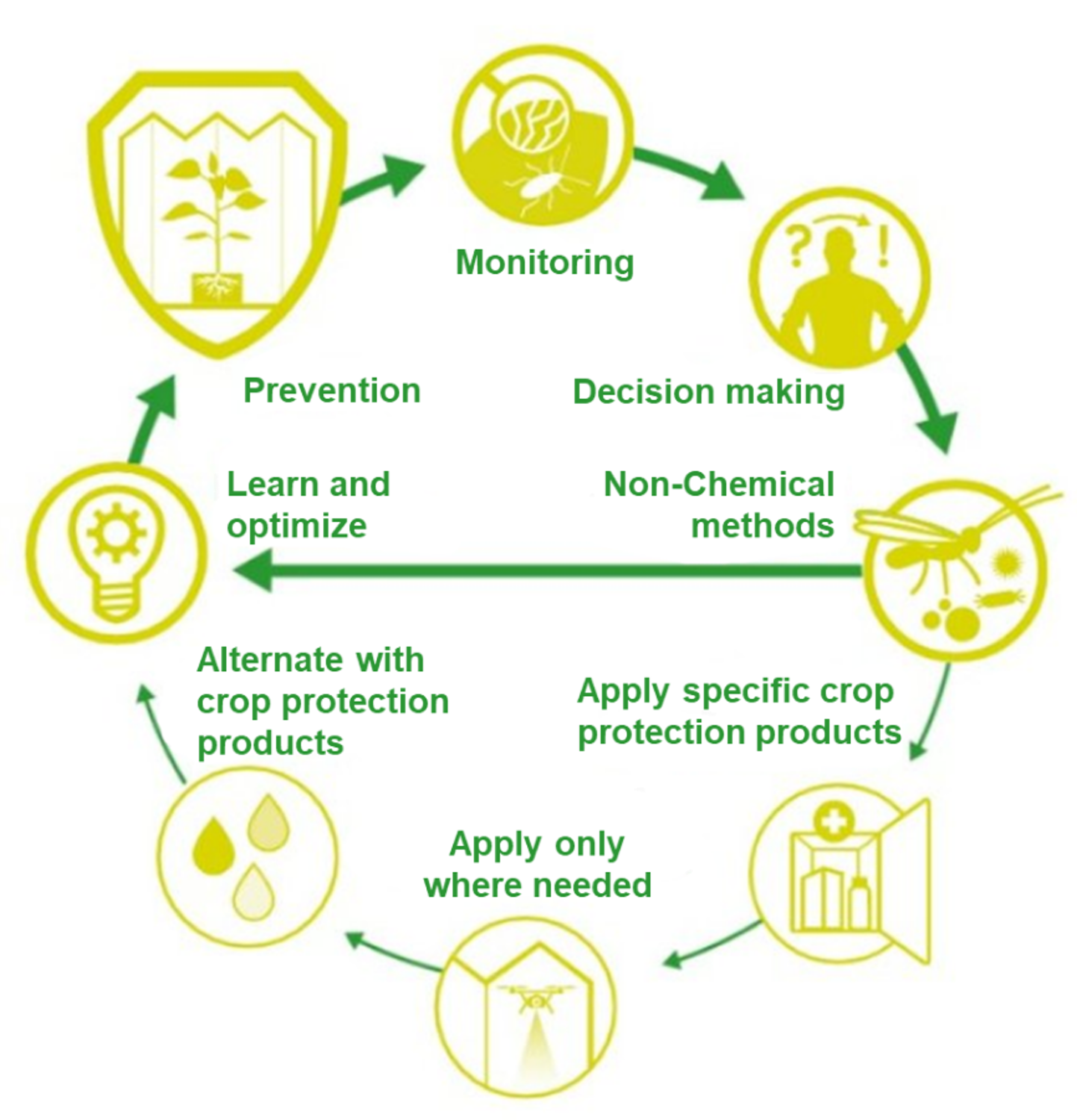

Despite IPM demanding individual solutions in each case, the concept of an integrated pest management program typically covers the following aspects:

- Problem assessment is the way to start an IPM program by deciding if the disease or pest presence is dangerous for a crop. A correct understanding of the infestation scope determines how a potential disease or pest should be prevented or controlled.

- Preventive measures intend to reduce infestations by applying different agronomic techniques. Prevention in integrated pest management may include crop rotation, planting disease or pest resistant varieties, the use of certified seeds and planting material but also the application of hygiene protocols and more efficient irrigations practices.

- Disease and pest monitoring are the next components of an IPM program because a decision is made to take a corrective action or not and how, based on the disease and pest level in a crop and other factors influencing pest or disease development.

- Decision making if an action is needed or not is based on the results of the disease and pest monitoring data. For the decision to be made the guiding principle is the planned IPM strategy of preventative and non-chemical methods

- Non-chemical methods means the application other technologies than traditional chemical crop protection products, e.g.

- Application of natural enemies

- Physical e.g. sticky traps / ground cover

- Pheromones

- Chemical correction, if there is no suitable or feasible non-chemical method to keep a pest or disease under control, a chemical crop protection product is applied, considering legislation, how and where to apply and choosing the least harmful option.

Transition to IPM in Vietnam

Sustainable and climate smart agriculture development remains high in the priority list of the Netherlands in Viet Nam, in line with the Strategic Partnership Arrangement (SPA) in sustainable agriculture and food Security of the Netherlands and Viet Nam. Focus of the government of the Netherlands in Viet Nam is the food system approach with the link towards sustainability, transparency and responsibility. IPM aligns very well with the food systems approach.

Successful implementation of IPM requires a holistic approach, starting from the propagation stages of plant material (seedlings) till the harvested produce leaves the farm. During these stages a wide variety of know-how and technologies needs to be applied to prevent the development of pests and diseases and minimize the application of chemical crop protection products as a corrective measure. In the case a correction action needs to be taken with chemical crop protection products, it is paramount this is done in the most efficient and safe way, including for the person applying the crop protection product. This is certainly a topic to which Dutch know-how and technologies can ensure that the application of crop protection products is done in the most efficient and safest way.

Adoption of IPM by Vietnamese farmers – IPM Lam Dong project

Vietnamese farmers are open to use more safe and sustainable production methods, and farmers have started to apply IPM strategies at their farms. For example, choosing disease resistant varieties, using sticky traps to monitor and catch pests and applying natural enemies to prevent or control pests. But more is needed for IPM to become the mainstream production method in Vietnam, such as training and knowledge development in IPM strategies, access to new technologies supporting IPM and demonstrating IPM technologies in the field. To address these points the project: “IPM and improved crop protection application methods for a sustainable food system in Viet Nam”, in short “IPM Lam Dong”, funded by the Dutch Government, was officially launched in October in Da Lat city during an IPM conference.

The main project objective of the IPM Lam Dong project is that IPM becomes the common practice of Vietnamese farmers to prevent and control pests and diseases with minimal use of chemical crop protection products, creating a safe and sustainable horticulture supply chain in Vietnam.

The project partners: Fresh Studio, Koppert, Da Lat University in close collaboration with PPD Lam Dong, will establish 3 IPM demonstration locations, and establish a training and IPM extension system to demonstrate to farmers IPM technologies, increase the knowledge level related to IPM strategies and provide technical support to farmers to apply IPM strategies at their farm. The project will run till end of 2026.

IPM Conference

To increase awareness about IPM and to officially launch the project the conference “IPM: Application of Biological Control Agents and official launch IPM project Lam Dong”, was organised in Da Lat, Lam Dong province on 8 October 2025. During the conference key stakeholders, such as Mr. Nguyen Quang Hieu – Deputy Director of the Department of Horticulture and Plant Protection, Ms. Ingrid Korving – Agricultural Counsellor, Embassy of the Netherlands, Mr. Rene van Rensen – R&D Director Crops, Fresh Studio and Mr. Rob Rippens, Business Manager Asia Pacific, Koppert and local representatives from the horticulture sector actively joined to present, discuss and learn from each other, about IPM and how to stimulate the adaptation of IPM strategies. The presence of over 200 participants and Dutch horticulture technology suppliers: Koppert, Rijk Zwaan, Enza Zaden, Bejo, BVB-Substrates, Royal Brinkman, Priva and Ridder is a clear indication that farmers and other stakeholders are very interested to learn more about IPM strategies and how to apply these strategies in practice n Vietnam.

As part the conference activities a field visit to one of the IPM demonstration locations was organised to see biological control agents of Koppert in action in a sweet pepper crop. Participants could observe that biological control agents, such as predatory wasps, bugs and mites imported from the Netherlands established and developed well in the sweet pepper crop, keeping pest insects such as spider mites, thrips, white flies and aphids under control.

In the coming period the IPM project Lam Dong will continue to its project activities to train farmers and demonstrate IPM technologies.

Visit of workshop delegation to IPM demonstration greenhouse