The Powering Aquaculture Progress (PAP) project is public-private partnership set to improve the modernization and development of aquaculture supply chains in Myanmar. It is the largest project with foreign direct investment in the aquaculture sector in the country. The team of Fresh Studio Myanmar is managing this project, in partnership with leading animal feed company De Heus, the Myanmar Fishery Federation, Pathein University and Golden Fish World hatchery. The project runs from 2019-2024.

During this five year period, the PAP project aims to achieve the following overall objectives:

- Creating access to modern input and technologies, therefore improving quality and access to inputs for farmers, mainly seed and feed;

- Improvements on technical knowledge and know-how of farmers, academic institutions, and technical support staff from private and public organisations;

- Improvement in efficiency of farming systems through transition towards more productive, shorter cycle and more diverse species, and increased transfer of adapted technologies;

- Support value chain coordination between independent actors and promotion of products toward consumers.

To achieve these objectives, the project has been broken down in three main work packages:

1. Access to inputs and technologies

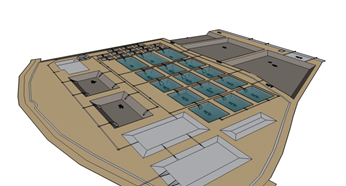

To make aquaculture a more profitable inclusive business that adds value to the local community, we will start by improving access to improved inputs and technologies, which is the backbone of any agricultural revolution. Our interventions consist of setting up the first fingerling feed production unit in Myanmar; establishing professional breeding centers, by modernizing two existing hatcheries; setting up the first Aquaculture Application Centre (AAC) in Myanmar, to apply knowledge and technologies from around the world.

2. Build capacity and professionalize all actors

Without proper capacity building and technical extension approaches, the adoption of improved inputs and advanced practices will be low, as they will not used properly and result in poor financial return. Our interventions consist of developing a technical team of local aquaculture specialists in key organisations (private & public); setting up satellite farms to transfer the work conducted on the AAC to the farmers; training of trainers embedded in key organisations to guarantee continuous training of farmers.

3. Strengthen farmers’ position in the chain

Improving the (production) capacity of fish farmers is the first step towards upgrading the aquaculture sector of Myanmar. To have access to finance and the market, there is the urgency to organize them. Our interventions include forming an independent producer organization; developing a quality standard and continuous improvement program among members; actively search for linkages and alliances between various actors in the chain.

The partnership is now in Year 2 and implementation has not been without challenges with the political developments and Covid-19 situation changing the political and business landscape in which the partnership is operating. However, the partners remain committed, and the work that ultimately aims to improve the income and food security of Myanmar’s people has become all the more relevant. Detailed plans for hatchery upgrading are on the way; the design for the Aquaculture Application Center is finalized and ready to be constructed after the rainy season in October; and soon a detailed training curriculum will be developed as a collaborative effort between all partners. The partnership is committed to achieve results!