Source: www.hortidaily.com

Following the growth of the horticultural industry in Vietnam, the team of Fresh Studio is expanding their consulting services by offering growers horticultural technologies as well. “We focus on technologies, which growers can directly use in their current production system. For example seeds, substrate, greenhouse film. In combination with an experienced team providing technical support we assist growers to be more successful in their production through these technologies”, Rene van Rensen with Fresh Studio explains. “Without the right base set of products and technical support, growing remains an uphill battle.”

High demand for knowledge

Last week, during the HortEx exhibition in Vietnam, there wasn’t a quiet moment for the team with Fresh Studio. The Vietnamese company has been active in consultancy for the Vietnamese horticultural industry and supports hundreds of growers in the country. Last year the Fresh Academy was established to help them do so: offering practical training for Vietnamese trainers helps expand horticultural knowledge throughout the industry rapidly. According to Rene, the demand for development, knowledge and support is high amongst Vietnamese growers.

Horticulture developing fast

“Horticulture in Vietnam is developing fast. Growers are eager to learn and to develop their skills”, Rene says. “This goes for the Dalat region, famous for its horticulture, as well as other regions like Moc Chau in the north of the country, where we’ve recently opened a new office.”

He continues: “All over Vietnam and in nearby countries, the demand for fresh produce is growing, but for safe and sustainable production there is still room for improvement. Luckily the Vietnamese government supports the industry and is eager to develop “high-tech” greenhouse production. Also through project initiatives taken to further develop the sector.”

For example, later this year Fresh Studio will help in establishing 8 nurseries in the province Son La. “Through this project farmers in Son La will get access to high quality seedlings helping growers to get a better crop performance. A great aspect of this project is that all nurseries will be managed by local female growers, as gender inclusiveness is an important objective of the project.“

Demand for supporting materials

Following these market developments, also the demand for better crop supporting materials is on the rise. “Growers willing to invest start with the base materials: Varieties, substrate, a greenhouse & film. If this base isn’t set properly, it will remain difficult to grow.”

Therefore Fresh Studio extended their consultancy activities and are now also offering growing solutions. The current assortment includes varieties (Semillas Fito, Pop Vriend Seeds, Agrico), substrates (BVB Substrates), biological crop protection (Koppert), greenhouse films (Agripolyane) and the products of Royal Brinkman.

Affordable and directly applicable

In the Vietnamese market growers don’t have much capital available, Rene explains. “We’ve chosen to focus on products that are of direct use to growers. These products are affordable and directly applicable, showing the benefits for the crop immediately.” “An imported greenhouse will certainly give a grower a better crop performance, but only if the grower makes sure he uses the right inputs for all growing aspects and has sufficient knowledge and management skills. We often see that growers still struggle with this and are not able to grasp the full potential of a crop. Therefore the market for investments in advance hardware are still limited. We don’t focus on this and are happy to refer interested growers to providers of these technologies, which we know.”

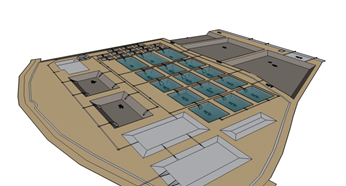

R&D farm

The products are tested and demonstrated at the Fresh Studio R&D farm in Dalat, a 1.1 hectare farm consisting of 4 greenhouses and open field production. “In our new activities, it’s not just about sales, it’s about offering a trusted solution to the growers”, Rene explains. “We’ve tested the products ourselves and know they’re from reliable suppliers. And we continue to combine this offer with our consultancy services, to support growers throughout the cultivation.” Consultation & crop support remain the most important services of the company. New in the field of services is the cooperation with Groen Agro Control, a Dutch laboratory, Fresh Studio makes it possible for growers to have their samples sent to the Netherlands and tested there. Apart from being more affordable and trustworthy, Rene explains the importance of the advice being offered with the test results. “Measuring an EC or a pH isn’t enough if you want to know how to adjust your fertilizer application. With the increasing acreage grown on hydroponics, advice on fertilizer application is becoming more important. So we are glad to start this service together with Groen Agro Control as it enables us also to better support the growers in Vietnam regardless of whether they buy our technologies or from others.”